To ensure the normal use of the valve, corresponding preventive measures should be designed

Release time:

Jun 12,2025

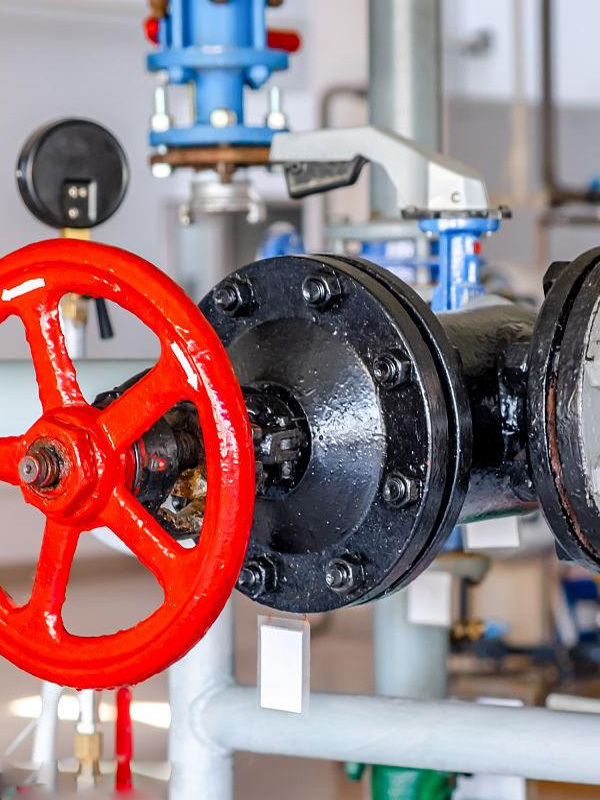

To ensure the normal use of the valve, install a filter at the inlet of the pipeline as much as possible. To prevent frequent fluctuations in pipeline pressure or temperature from reducing the service life of valves, corresponding preventive measures should be designed.

To ensure the normal use of the valve, install a filter at the inlet of the pipeline as much as possible. To prevent frequent fluctuations in pipeline pressure or temperature from reducing the service life of valves, corresponding preventive measures should be designed.

To ensure the normal operation of the valve and extend its service life, it is recommended to install a filter at the inlet of the pipeline. This can effectively remove impurities from the fluid and reduce the risk of valve wear and blockage. At the same time, in order to cope with fluctuations in pipeline pressure and temperature, the following preventive measures should be taken: first, conduct pipeline pressure testing to ensure stable system pressure; Secondly, implement temperature monitoring and regulation to ensure that the fluid temperature is within the appropriate range of the valve material; Finally, regular maintenance and inspection should be conducted to promptly identify and resolve potential issues. These measures help ensure that valves operate in a stable working environment, improving the safety and efficiency of the system.

Next Page

Recommend

About the classification of gate valves

Jul 15,2025

CONTACT US

Zhejiang Yuhuan Science and Technology Industrial Functional Zone (Huxin Section)

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.